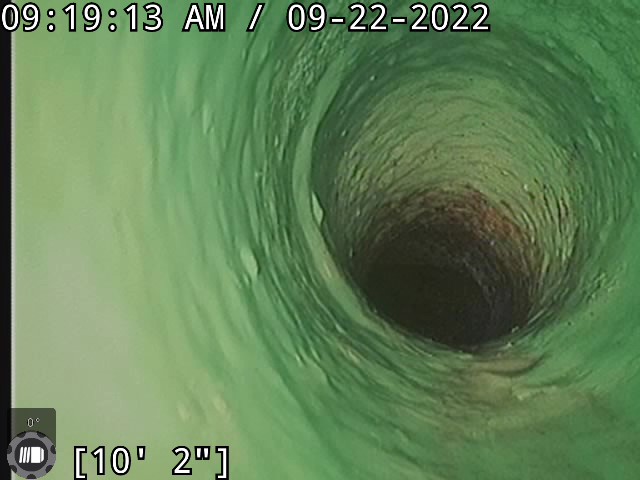

Albany – NY. A large management company in the Capital Region was for a solution to some sewer line issues they were having. The issue took place inside of the many apartment buildings on the property, and it began with a leaking tub drain. One of our Trenchless technicians began a camera inspection from the toilet flange in the bathroom, and found that the bottom of the 4″ cast iron sewer line had completely deteriorated.

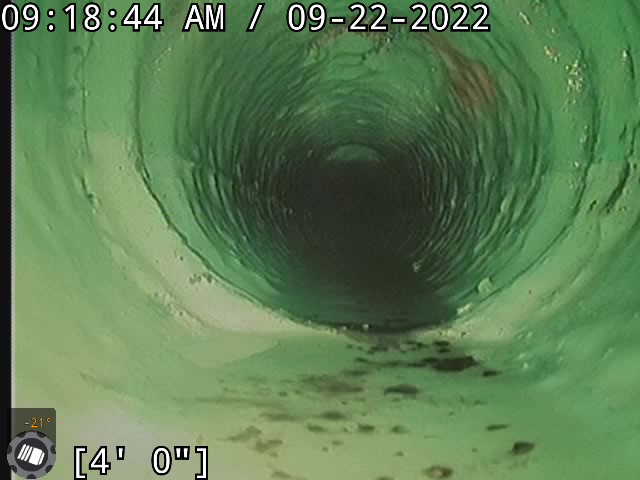

Water had begun pool underneath the tub due to this, and started making the issue worse. Our technician determined that the best solution was to install a new epoxy coating from the toilet flange in the bathroom over to the 4′ sewer main roughly 10ft away. After the new line was installed, the crew also exposed the broken tub drain, and replaced that with PVC as well. Additionally while on site the crew discovered additional issues within the main trunk line of the building. A camera inspection revealed that near one of the lateral tie ins there was a hole in the sewer line, causing additional problems.

The crew determined that descaling the pipe, then installing a new UV Inversion pipe, roughly 30′ long. After the new liner is cured they would then cut back in three reinstatements for lateral lines, and ensure 100% flow of all sewer lines leading to the trunk line. The job collectively took about 1-2 days to complete, but it was spread out over the course of 1-2 weeks. This included mobilization, set up, prep work, and breakdown.