JFK Airport – Jamaica. NY. A kitchen within the JFK Airport was having a drain line issue that needed to be remedied. There were a few sections with holes and cracks in it. This was a different job than the crew is used to; it was in a “cleanroom” and the techs had to wear appropriate PPE. They also used a special type of liner, Max WovoLiner 3D Brawoliner, that is extremely flexible, and could be blown in through the 4′ PVC floor trap.

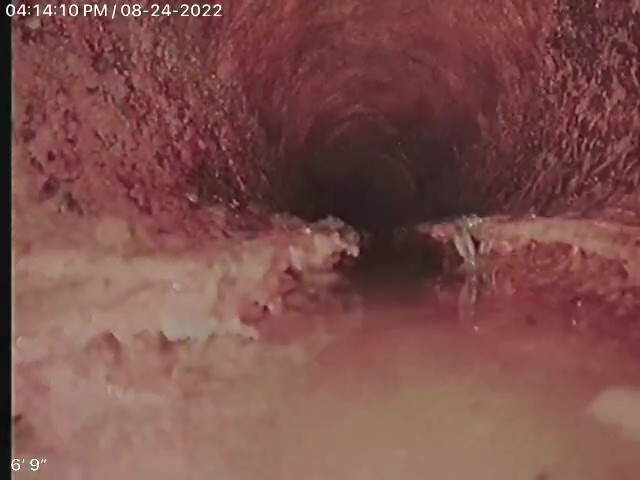

This liner was cured via steam. Prior to blowing in the liner, the crew cleaned and descaled the line in preparation for lining.

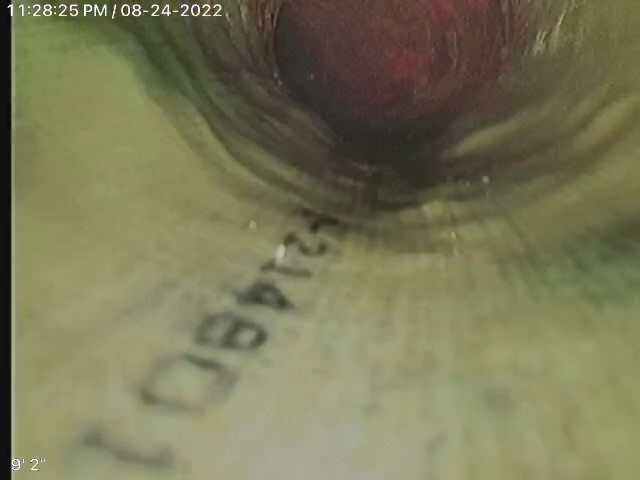

After the completion of the liner, it was then camera inspected to ensure there were no imperfections, and it had cured properly. This job took roughly half a day to complete, including mobilization, set up, prep, lining, and breakdown.