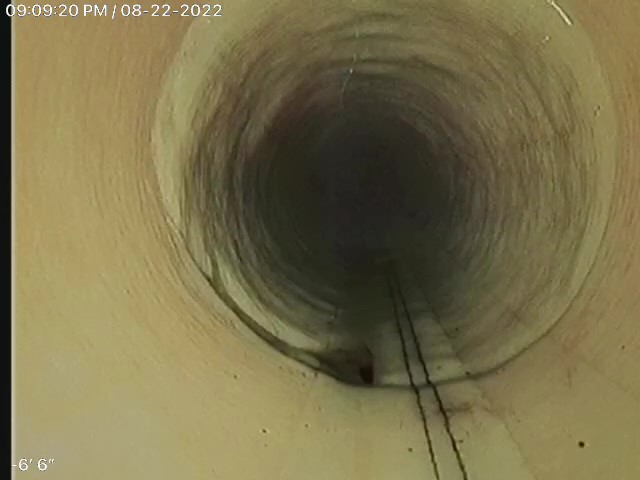

Blairstown NJ – The customer was having issues with their cast iron sewer line going from their house to their septic tank. The line was roughly 65ft long and had numerous areas with cracks and holes in it. The crew used a 4″ transitional flex liner and cured the line using a steaming process. The line was then camera inspected post lining to ensure the liner adhered to the walls of the pipe properly. This job took a day to complete, including mobilization, set up, prep, lining, and breakdown.